FRAGRANCEDOS – FS

Table of

contents

Page

1. Function ............................................................................................................................

2

2. Technical data .................................................................................................................

2

3. The fragrance

pump ......................................................................................................

2

3.1 Changing the

hose set ................................................................................................

2

3.2 Dosing valve and

protection suction filter...............................................................

2

4. Console for the

fragrance canister .............................................................................

3

5. Installation /

commissioning / dosing performance ............................................... 3

6. Maintenance .....................................................................................................................

4

7. Wiring circuit.....................................................................................................................

4

1.

Function

The dosing unit FRAGRANCEDOS

doses fragrance oil concentrate into the steam tubing of a steam cabinet in

adjustable intervals of 1-10 minutes. The dosing quantity and so the

aromatization intensity is also adjustable from 0-120 seconds.

2. Technical data

The dosing unit

consists of:

-

the injection

pump with special resistant hose and integrated controller

-

dosing

performance: max. 1 litre per hour

-

Max

suction hight: 1,

power requirements

100-240VAC, 12VDC or 24VDC. It is under what kind

of pump used, and it can be custom-specified.

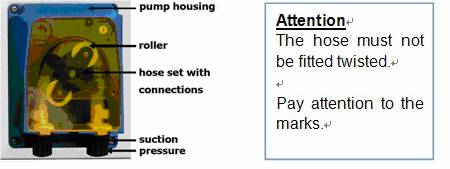

3. The fragrance pump

A injection pump is used to dose the fragrance.

The pump is ideal for achieving low dose rates and is self priming (i.e. no air

bubbles). Rotating rolls press the dosing hose against the pump tube housing,

whereby the liquid within the hose is pressed out in front of the rolls and at

the same time drawn in behind them. The pump is extremely reliable and very

simple to handle.

3.1 Changing the hose set

Remove the

transparent pump cover and the yellow roller cover. To change the hose set the

suction and pressure connections have to be pulled forward. Turn the roller to

the right and pull out the pump hose over the cut out at the roller. On

reassembly reverse this process. At the installation act contrariwise.

3.2 Dosing valve and protection suction filter

A back pressure of

steam into the fragrance tube is prevented safely by a spring loaded non-return

valve. The valve body is completely made of stainless steel. The suction filter

helps the tube to be properly fitted in its seat.

Dosing

valve for fragrance

Dosing

valve for fragrance

dosing valve

suction

filter

4. Console for the fragrance canister

The

standard version is delivered for wall mounting the fragrance canister is set

on the ground.

The

console is made for larger sizes of containers helping to keep the floor space

clear.

5. Installation / commissioning /

dosing performance

The unit has to be mounted in an easily accessable place. The fragrance canister is placed under the unit on the floor and the suction tube is hung onto it so that the end of the hose reaches the bottom of the canister. Make sure the protection lid of the liquid end is properly fitted in its seat.

For

shipping and stock-keeping there’s no hose inserted in the pumps preventing a

deformation of the hose.

The

dosing/ non-return valve 3/8“ is screwed into the tapping point. The dosing

tube is sheathed in an outer safety tube and connected to the dosing valve and

pump outlet. (Right hand side connection).

Attention! Do not split the dosing

tube when fitting!

Place

the canister with the fragrance oil concentrate under the dosing pump, and put

the suction lance into the canister. Set the rotary button on zero until you

see the fragrance being drawn up (sucked up).

FRAGRANCEDOS

Pause

time

Pause

time

0 = no pause time

10 = 1 minute

20 = 2 minutes

30 = 3 minutes

… …

100 = 10 minutes

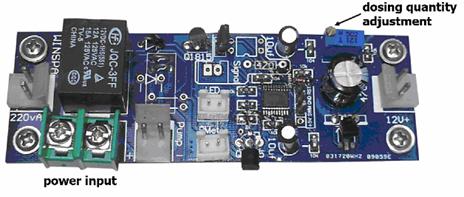

Afterwards adjust

the required dosing programme by the rotary button on the housing: the dosing

pump conveys 5ml of fragrance per dosing impulse. For bigger steam rooms the

dosing quantity can be adjusted on desirable (0- 100) ml per dosing impulse

(see wiring circuit)

We recommend to

combine the dosing of the fragrance with the function of the steam generator:

e.g. interlock the power socket or install a temperature sensor to ensure

dosing is distributed through the tubing into the steam cabinet when steam is

being generated.

6. Maintenance

The FRAGRANEDOS

pumps are practically maintenance-free and give long life if the following

points are considered:

-

unsuitable

fragrances are not used

-

check

the pump head every time you change the canister

-

change

the hose twice annually, if required monthly.

If the

unit is taken out of service remove

the dosing hose from the pump to prevent long term deformation of the hose. The

pump head should be checked frequently to assess condition of the peristaltic

hose and the roller springs (i.e. no corrosion/wear), if so change peristaltic

hose and if necessary roller too. At least once a year the peristaltic hose

should be replaced. If not checked, leakage could occur and damage the pump.

For exchange cut off

suction and injection tube at tube connector, fit the new ends to the

connectors of the new peristaltic hose and fit it as described above.

Trouble Shooting:

“no

fragrance dosing – no aroma in the Steam Room?”

Points to check:

-

Fragrance

canister empty?

-

![]()

![]() Does

the pump get voltage? Pause time on “

Does

the pump get voltage? Pause time on “

-

Check

the fragrance on pureness and cleanness.

-

Check

the function of the pump: Pull the suction hose of the pump out of the

fragrance canister – does a air bubble appear in the hose? Is it aspirated? If

yes, the suction function of the pump works. Is the roller of the pump

rotating?

-

Check

the pump hose on cracks, deformation.

-

Check

the roller of the pump on tracks of wear, springs broken, is the hose mounted

correct?

-

Check

the dosing valve (blocked, clotted?) Remove the dosing tube from the valve by

opening the cap nut of the hose connection(Pay attention that no fragrance

splashes out as the hose is on pressure).

Switch on the pump. If

fragrance is pressed out of the tube the pump works properly. Unscrew the

dosing valve of the steam tube and make the same test. If no fragrance is

pressed out of the dosing valve it is blocked.

7. Wiring Circuit