|

|

MANUAL

|

Models

|

WS30 WS40

|

WS60 WS80

|

WS150 WS180

|

|

WS50 WS60

|

WS100 WS120

|

Autodrain Built-in

|

|

Attaching Autodrain

|

Autodrain Built-in

|

3.0kW

4.0kW

6.0kW 8.0kW

5.0kW

6.0kW

10.0kW 12.0kW

|

15.0kW

18.0kW

|

STEAM

GENERATOR

|

Please read the manual carefully before using the

steam generator.

WinSpa Steam

Generator

IMPORTANT ............................................................................................................................................3

Before Installation.. 4.................................................................................................................................4

Steam Room Guidelines. ........................................................................................................................4

Using Steam Room / Warning. ................................................................................................................4

Steam Generator Parts. ........................................................................................................................5

Instructions of Use.. ........................................................................................................................5

On/Off mode. ........................................................................................................................5

Warmstart / Standby Mode. ....................................................................................................6

Temperature / Timer. ...............................................................................................................6

Changing the Values. .............................................................................................................7

Cabin Light......................................................................................................................... 7

Key Lock.............................................................................................................................. 7

Auto Drain........................................................................................................................... 7

Steam Room Extractor Fan.............................................................................................. 8

Optional Features. ..................................................................................................................8

Built-in Scent Pump. ...................................................................................................................8

Operating Steam Room.. .............................................................................................................9

Maintenance.. ............................................................................................................................................9

Decalcification. ........................................................................................................................9

Level probes cleaning................................................................................................................. 10

Tank Cleaning. ........................................................................................................................10

Assembly and Installation.. ............................................................................................................11

Plumbing. ..................................................................................................................................12

Water Supply. ........................................................................................................................12

Steam

Outlet. ........................................................................................................................12

Pressure Relief Valve. ....................................................................................................12

Steam Head. ........................................................................................................................12

Drain.................................................................................................................................. 12

Attaching Autodrain........................................................................................................ 12

Power Wiring.................................................................................................................... 13

Technical Data................................................................................................................... 13

Electrical Diagram.. ........................................................................................................................14

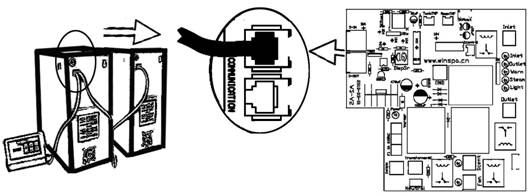

Connection of WINSPA Control to PCB. ................................................................................15

Installing Control Unit. ..................................................................................................................15

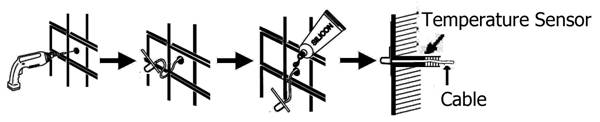

Installing the Temperature Sensor. ..................................................................................................16

Steam Generator Series Connection. ...............................................................................................16

Troubleshooting.. ............................................................................................................................................17

Checking and Fault-finding. ....................................................................................................17

Checklist. ............................................................................................................................................18

Warranty.. .......................................................................................................................................................21

Table of Spare Parts Replacement..................................................................................................... 22

|

IMPORTANT

l

Do

not make sharp bends or elbows along the steam pipe.

l

The

steam head must be installed with outlet facing down to floor.

l

Do

not allow the sags or water pocket along the steam pipe and/or the

ventilation duct. IMPORTANT!

There must not be any type of obstruction along the steam line, such as a

stop-off valve or tap. The internal diameter of the steam pipe must not be

reduced.

l

Ensure

that steam rooms that are used continuously for more than 2 hours at a time

are ventilated by 10-20 cubic meters of air per person and hour.

l

Booster

pump is not allowed to be installed in front of water inlet line.

l

IMPORTANT! The ambient temperature outside

the steam room and around the steam generator must not exceed 350C.

l

Place

the steamroom temperature sensor as far away from the steam jet as possible.

l

De-scale

the steam generator at regular intervals as instructed. In hard water areas,

where calcium levels exceed 6 dH, we recommend the installation of a water

filter and/or softener.

l

Clean

the steam room regularly.

l

CAUTION! Stay at least 12” (30cm) away from hot steam escaping from steam outlet.

l

IMPORTANT. The steam generator’s waste pipe must always

discharge into a drain outside the steam room itself. The water is very hot.

|

Before Installing

Use

the following information together with the consultation of your

contractor, architect or designer in determining all factors necessary in

providing a suitable and safe steam room.

Check

that the supply voltage is suitable to your steam generator.

Ensure

that the steam generator kilowatt corresponds to the volume of your steam room.

Refer to Technical Data (Page 13)

Steam Room Guidelines

1. The Steam Room must be

fully enclosed, complete with walls, door, flooring and ceiling.

2. Rubber linings (e.g.

gaskets) are recommended for the door to effectively seal the heat and the

steam inside the Steam Room.

3. If tiles are used for

the flooring or some other smooth surface material, provide suitable anti-skid

strips or rubberized mats to prevent slipping resulting to injury.

4. Materials used for the

walls and ceiling should have water-resistant, non-corrosive surfaces such as

tiles, marbles, molded acrylic, or other non-porous materials. The ceiling

should be dome-shaped to prevent the dripping of condensate.

5. A drain must be provided

in the flooring.

6. Heating, venting or air

conditioning devices should not be installed inside the Steam Room.

7. Steam Room windows

should be double paned.

8. Limit the Steam Room

ceiling to a height of 2.5 meters. Exceeding 2.5m will require a higher-rated steam generator.

Using Steam Room

Warning

All

generators is connected to 240/415 volt power supply. All service work to be

performed by a licensed, qualified electrician.

Bathing time should not exceed 30

minutes; extending bathing time may cause rapid heart beat, headache, dizziness

or weak feeling. If any of the above symptoms occur leave steam room

immediately.

People

with following conditions should not use steam room unless advised safe to do

so by a doctor:

(1).

Pregnant woman (2). Heart condition (3). High blood pressure

(4). Diabetes (5). After consumption of alcohol (6). On any

medication.

Children

should not be left unattended or alone in steam room.

Do

not touch steam head during operation or scalding will occur.

For

any reason should over heating occur, immediately open door to reduce

temperature.

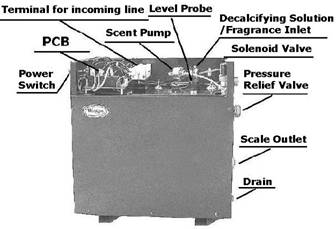

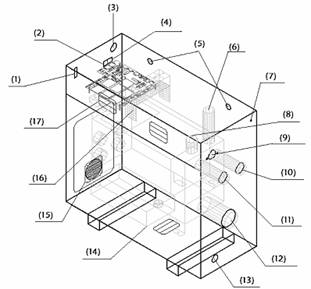

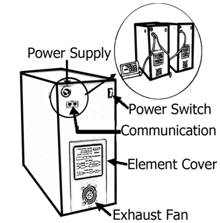

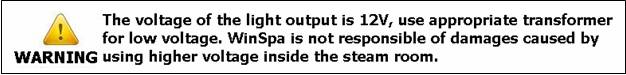

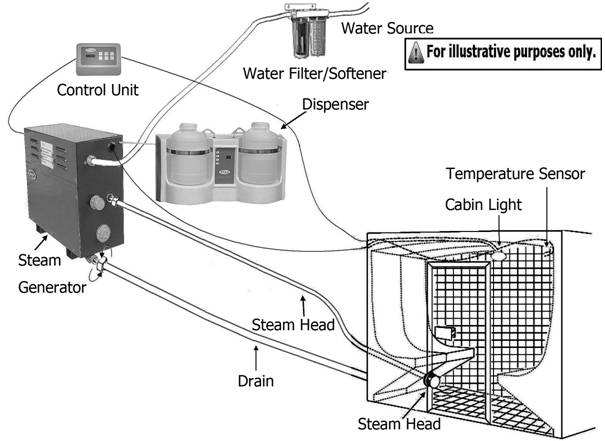

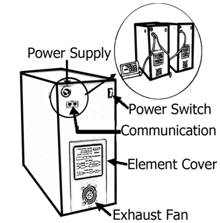

Steam Generator Parts (Figure 1)

(1) Power switch;

(2) Communication adapter; (3) Hole for Power supply cable; (4) Communication;

(5) Fixing holes; (6) Fragrance/Decalcifying Solution inlet; (7) Fragrance tube

inlet; (8) Water level probe; (9) Water inlet; (10) Pressure relief valve; (11)

Steam outlet; (12) Scale outlet; (13) Drain; (14) Transformer; (15) Exhaust

fan; (16) Terminal for incoming line; (17) Lights output.

Instructions of use

When

power supply to steam generator is switched on, a high beep will confirm the

supply and the screen displays the generator tank’s temperature.

There

are four different operation modes in the control unit: On/Off, Warmstart,

Timer/ Temperature and Light. The user can easily set the unit, making the

steam bathing more convenient with less energy consumption.

Press

On button on the control unit to activate the generator. When

generator is active, the control unit alternately displays time and temperature

in steam room.

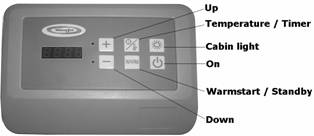

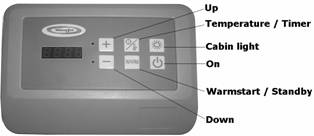

Figure 2

On/Off Mode

On/Off Mode

When

the power switch of steam generator is turned on, press On/Off on control panel

to activate steam generator.

|

Once generator is activated, the

screen alternatively displays time and the set temperature in steam room.

|

Warmstart / Standby Mode

Warmstart / Standby Mode

Activate warmstart-mode

if the steam room is not used constantly.

During the

warmstart-mode the water in the steam generator tank is kept hot, with minimal

energy usage. The generator is able to produce steam shortly after pressing On

button on the control panel for the convenience of the user.

The default setting of

warmstart is of OFF-mode. To activate, press WARM button, the screen displays

OFF, press WARM button again to change to ON (= OH) mode.

To set / change

remaining warmstart time press and hold the WARM button for 4 seconds, then

press up or down buttons.

When warmstart is set to

00:00 and on ON-mode, auto drain feature will not be available.

When warmstart time

expires, cabin light and generator go off automatically.

To activate on-mode

again short press the WARM button to ON (= OH) mode.

Temperature/ Timer

Temperature/ Timer

The temperature/timer

button can be used to switch between the temperature and session time.

When the power switch of steam

generator is turned on, the tank temperature is displayed. To set/change

temperature at desired level press up and down buttons directly. The default

set temperature is 450C degree. (maximum temperature possible is 600C degrees).

|

Under temperature control only

the temperature in the steam room will be kept in the preferred set

temperature with continuous discharge of steam. The generator will keep

running until it has been switched off manually. In this mode the light

also needs to be manually turned off.

|

If the temperature/timer

button is pressed, the remaining session time will be displayed. It can be

changed by pressing up and down buttons. The temperature / session time will be

saved as default settings if there is no buttons are pressed within 4 seconds

and the display will return to tank’s temperature until generator is activated.

Press On button and screen displays

00:00 then short press up or down button to set session time. When session time

is set 00:00 generator will keep running until warmstart time expires or it has

been manually switched off.

|

When under both temperature and

timer control and warmstart is of OFF-mode generator and cabin lights will be

switched off automatically when session time expires.

|

Changing the values

Changing the values

Pressing up or down

button in control unit will increase or decrease the currently

displayed value. A value cannot be in- or decreased above or below its maximum

or minimum value.

The up and down buttons

are repetitive. Holding the up or down button will cause the value to in- or

decrease with an increased rate.

If no keys are pressed

within 4 seconds, changes in the values are confirmed.

If no keys are pressed

for 4 seconds, the display will automatically display the water tank

temperature.

Cabin Light

Cabin Light

The cabin light must be

switched on manually. It can be manually or automatically switched off:

a. If session time is set,

cabin light goes off automatically 15 minutes after session time expires.

b. If warmstart time is set

and warmstart is on On-mode, when warmstart time runs off, cabin lights switch

off automatically.

c. If warmstart time is set

to 00:00 and warmstart is on On-mode, however no session time is set, cabin

lights must be switched off manually.

d. When generator is under

temperature control only, cabin light must be manually switched off.

Key Lock

Key Lock

Lock and unlock the key

pad by pressing or holding On button for 4 seconds, the screen shows current

mode: ULOC = Unlock, LOC = LOCK, press either up or down buttons to change the

mode.

Only On/Off, warmstart

and cabin light buttons are usable when the control unit is locked. If other

buttons are pressed, relative current status is shown in the display.

The key

lock function is set automatically if it was left active during the previous

operation.

Auto Drain

The auto drain feature

automatically drains the water system after every use. The tank is flushed and

will remain empty until the steam generator is used again.

After the warmstart time

runs out, control unit automatically goes to Auto Drain mode. After hot water

drains, the generator’s tank will be flushed with cold water and then drains

again,which restrains scale from

forming on the inside surface of tank and heating elements . The draining

process will take about 10 minutes.

Steam Room Extractor Fan

The steam room extractor

fan feature will draw out the vaporous wastes from previous use. The extractor

fan will be activated automatically when session time expires.

Long press cabin light

button for 4 seconds, the control unit displays remaining steam room vaporous

wastes extracting time. To change the remaining exhaust time press up or down

button.

The default extractor

fan time is 10 minutes, maximum exhaust time can be set is 240 minutes. When

the extractor fan time is set 00:00, extractor fan on steam room will keep

operating until generator goes On-mode again.

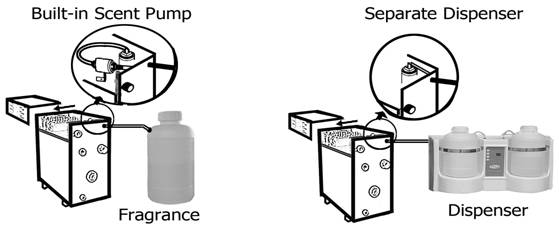

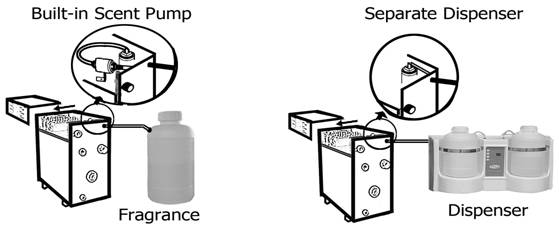

Optional Feature

User can choose generator

with Scent Pump built in or a separate WinSpa Doser Unit. Figure 3

Built-in Scent Pump

Built-in Sent pump will

be operated when generator goes On-mode. Before switching generator on make

sure there is enough aroma in the aroma container. Never run the scent pump

dry.

Aroma oil will be filled

with each water recruitment of steam generator for 2 seconds. When session time

expires or generator is turned off, scent pump will turn off too. It will take

about 10 seconds for every 1 meter of pipeline for aroma liquid to reach the

pump.

Fragrance container

should be placed at the same level with steam generator. Never place the

container upper or lower than generator. Make sure to fill the pipeline fully

with water using the injector in the pack.

When aroma oil is

changed, check that the pipeline is not broken and is full of liquid. It is

also recommended to wash the fragrance container between changes, especially

when using different fragrances.

Use only fragrance meant

for steam generator use. Follow the instructions in the fragrance packing.

Figure 4

Operating Steam

Room

1. Ensure power

supply to steam generator is switched on.

2. Ensure water

supply is turned on.

3. The steam room is

now ready to use, press On button on the control unit

to activate

the

generator.

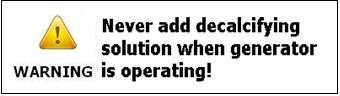

Maintenance

1. Decalcification

Tap water contains impurities, for example lime, that

can cause calcium deposit and block the internal parts of the steam generator.

To prevent this and prolong the lifetime of steam generator it is recommended

to have a water filter and water softener. They are connected to the water

source of steam generator’s water inlet.

Follow these

guidelines to perform preventative maintenance of steam generator.

|

|

Figure 5

|

|

①. Turn on the generator and press WARM

button to switch on warmstart mode and wait until water inside generator tank

starts to boil. Disconnect steam generator from main power supply before

opening generator’s cover. Only licensed electrician or professional

maintenance person can open covers and do cleaning.

|

②. Use adjustable wrench to remove the tube cap of the

scale remover inlet. Before opening, make sure that the generator is off. Cool

down the angled tube with wet cloth if needed.

③ Pour

the solution through tundish into the water tank. Do it slowly enough to

prevent solution to splash into the generator.

④ Close the cap firmly and let the solution stay in the

tank for 30 minutes. Do not switch the generator on.

⑤ Drain the water tank by activating the generator for

2 minutes. Press On button again manually to start auto drain.

⑥ Repeat

the step 5 two more times.

Use Decalcifying Solution as

follows:

|

Steam Generator (kW)

|

Decalcifying Solution

(ml)

|

|

3 - 8

|

250

|

|

10-18

|

500

|

For steam generators in commercial use (over 5 hours

continuously daily) additional service plan is recommended three times a year.

Please contact your service center for details.

Frequency for decalcification:

Unit dH where 1 dH is 10 mg calcium in 1

liter of water

< 30 dH = very soft water,

decalcification every 500 operation hours

3-60 dH = soft water,

decalcification every 100 operation hours

6-90 dH = hard water,

decalcification every 50 operation hours

9-180 dH = very hard water,

decalcification every 30 operation hours

2. Level probes cleaning

Tips of WinSpa Water level probes are

protected by a patented coating from scale attaching. For generator in

commercial use (over 5 hours continuously daily), service plan is recommended minimum 4 times

a year.

a.

Disconnect steam

generator from main supply before opening generator’s covers. Only licensed

electrician or professional maintenance person can open covers and do cleaning.

b.

Use adjustable wrench

to deattach 2 wires from level probes. Make sure that when connecting wires

back, wires are connected to right probe.

c.

Use adjustable wrench

to remove level probe. Clean tip of the pins from impurities using sandpaper

and replace coatings on tip in every cleaning service! Don’t damage plastic

coating on pins. If coating is damaged, replace level sensor. Tighten level

sensor by hands and use adjustable wrench only for final tightening.

3.Tank cleaning

a. Disconnect steam generator from

main supply before opening generator’s covers. Only licensed electrician or

professional maintenance person can open covers and do cleaning.

b.

Open side cover of

heating elements.

a)

Disconnect heating

elements and exhaust fan.

b)

Remove heating elements

and clean deposits from the elements.

c.

Open the scale outlet

plug on side of generator using adjustable wrench.

a)

Remove deposits from

bottom and sides of the tank and wash away deposits. Don’t use auto drain valve

since big particles can block the valve.

b)

Attach the plug and use

Teflon pipe seal if needed.

c)

Screws in the heating

elements. Make sure that heating elements and exhaust fan are connected

correctly. Figure 6

Assembly and Installation

1). Location of the steam generator has to

be near the steam room. Place it within 7.5 meters to the steam room.

2). Steam generator has to be installed

outside the steam room.

3). The steam generator must not be installed outdoors

or areas that may damage the unit due to climate conditions.

4). Do not install the steam generator or plumbing

lines in unheated attic or any locations where water could freeze.

5). The steam generator must not be installed in areas

near flammable or corrosive materials or chemicals such as gasoline, paint

thinners, chlorine or the like.

6). Provide a level surface to install steam

generator. Side hole slots are provided for wall mounting. Make sure that the

steam generator is secured and is level when mounted on the wall.

7). The steam generator has to be installed

in an upright position only.

8). Install water filter and softener or

alike when necessary.

9). Leave enough space for service and

maintenance of the generator.

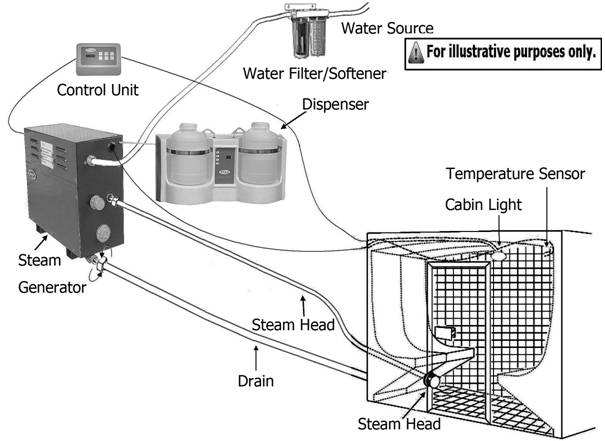

Figure 7

Plumbing

All

plumbing has to be installed by a licensed qualified plumber. Plumbing should

be in accordance with national or local codes. Use unions for piping

connections. Use only 12mm (1/2”) brass piping or copper tubing. Never use black or galvanized pipe for the plumbing as it can easily crack or damage.

Water Supply

Provide

a shut off valve on the water source for the steam generator. Turn off the

inlet water line before installing the unit. Recommended water pressure is 1 to

3 bar and maximum water pressure without water filter/softener is 4 bar. Water

softener is recommend to use.

Steam Outlet

The

steam must move in a continuous flow to the steam room. Do not install valves

on the steam line. Use insulated, rated 1200C or higher, brass pipe or copper tubing for steam line to connect to the steam head as permitted by codes. Slope the steam line height by 20mm per meter towards the steam head to avoid trapping of the condensate and eliminate steam trap that blocks the flow of the steam. Never use bends wherever possible. But when

necessary always install sweeping bends to allow easy flow of steam.

For

best operating results install a 20mm (3/4”) line. Two steam outlets are required for generator up to 18kW, however, for generators up to 6kw a 12mm (1/2”) line will suffice.

Pressure Relief Valve

The

pressure relief valve activates when there is an overpressure in the steam

line. It automatically opens and releases the pressure steam. When this

happens, please check your steam line for servicing.

|

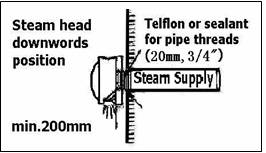

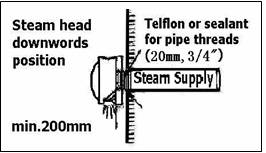

Steam Head

Figure

8

Install steam head in location to avoid

body contact and scalding. The steam head must be installed with outlet

facing down to floor. Seal thread using Teflon tape and do not over tighten.

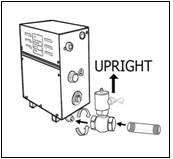

Drain

|

|

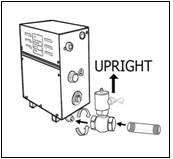

Drain

valve is installed inside steam generators over 6.0kW, for generators below

6.0kW a drain valve is provide for maintenance. Set drain connection for your

steam generator according to national or local plumbing requirements. Make sure

the valve is installed upright. When connections are made always use two

wrenches/spanners.

|

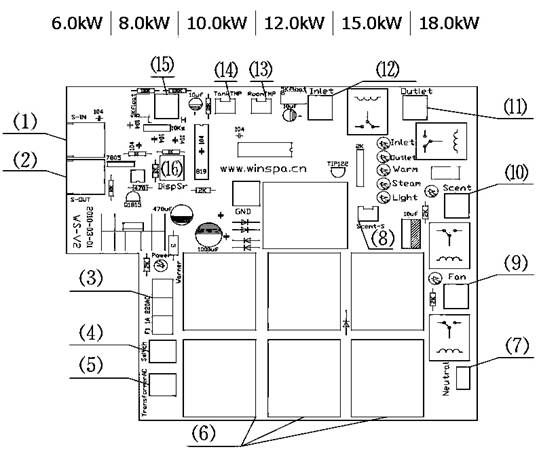

Attaching Autodrain Figure 9

(for 3.0~ 6.0kw steam generator)

1.

Attach

the autodrain to the outlet. Make sure the valve is installed upright. Union is recommended when connecting pipeline .

2.

Plug

the wire into the plinth on circuit board of steam generator.

|

|

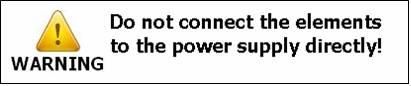

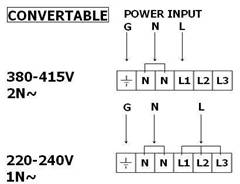

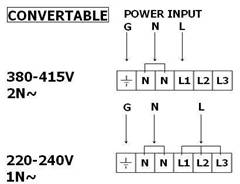

Power Wiring

Only

a qualified electrician should do the Electrical wiring connections.

Check

the power supply before installing your unit. Single Phase connection, a 220 –

240V supplied is required. Use two-wire supply source and equipment grounding

wire for single phase connection. Check size of wires in Ampere Chart in

accordance with the National Electrical Code and local electrical code.

The

installation must include switch for all pole disconnection. Circuit breaker

with 3mm control gap is recommended.

Technical Data

|

Model

|

kW

|

Steam Room Volume (m3)

|

Voltage

(V)

|

Current

(A)

|

Phase

|

Wire Size mm2

|

Size of Steam Room (mm)

|

|

Width

|

Depth

|

Height

|

|

WS 30

|

3.0

|

3 max

|

220-240 /

|

14

|

1N /

|

4.0

|

430

|

170

|

360

|

|

380-415

|

8

|

2N

|

2.5

|

|

WS 40

|

4.0

|

4 max

|

220-240 /

|

17

|

1N /

|

4.0

|

430

|

170

|

360

|

|

380-415

|

10

|

2N

|

2.5

|

|

WS 50

|

5.0

|

3-6

|

220-240 /

|

22

|

1N /

|

4.0

|

430

|

170

|

360

|

|

380-415

|

8

|

2N

|

2.5

|

|

WS 60

|

6.0

|

3-10

|

220-240 /

|

26

|

1N /

|

6.0

|

430

|

170

|

360

|

|

380-415

|

9

|

2N

|

2.5

|

|

WS 60

|

6.0

|

3-10

|

220-240 /

|

26

|

1N /

|

6.0

|

480

|

200

|

420

|

|

380-415

|

9

|

3N

|

2.5

|

|

WS 80

|

8.0

|

8-20

|

220-240 /

|

37

|

1N /

|

8.0

|

480

|

200

|

420

|

|

380-415

|

19

|

3N

|

4.0

|

|

WS 100

|

10.0

|

9-22

|

220-240 /

|

46

|

1N /

|

10.0

|

480

|

200

|

420

|

|

380-415

|

23

|

3N

|

6.0

|

|

WS 120

|

12.0

|

15-28

|

380-415

|

28

|

3N

|

6.0

|

480

|

200

|

420

|

|

WS 120

|

12.0

|

15-28

|

380-415

|

28

|

3N

|

6.0

|

480

|

250

|

420

|

|

WS 150

|

15.0

|

22-40

|

380-415

|

19

|

3N

|

4.0

|

480

|

250

|

420

|

|

WS 180

|

18.0

|

26-45

|

380-415

|

28

|

3N

|

336.0

|

480

|

250

|

420

|

NOTE:

This table is for steam rooms built in with light

walls (tempered glass or acrylic). Steam rooms with thick walls or ventilation,

please use higher kilowatt steam generators.

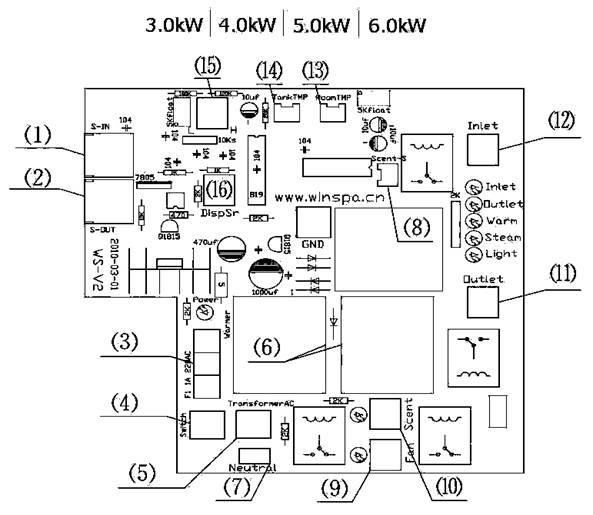

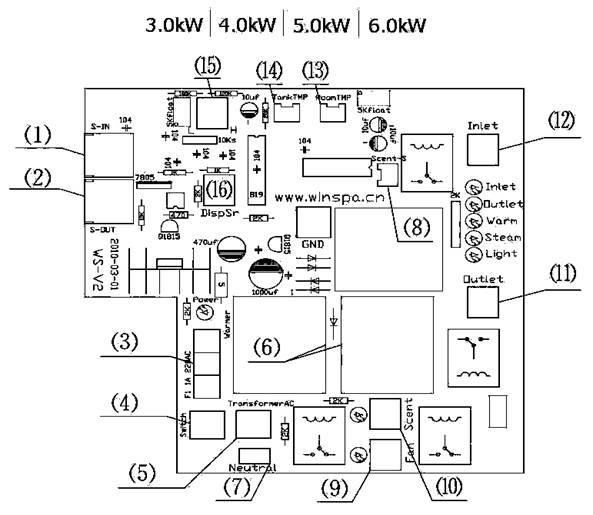

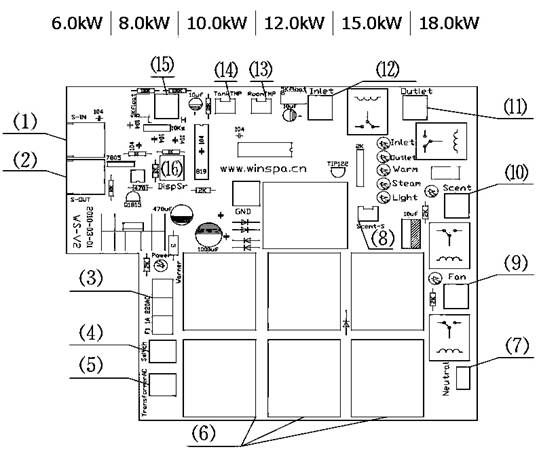

Electrical Diagrams (Figure 10)

Circuit Card

(1)=Communication;

(2)=Communication adapter; (3)=Fuse; (4)=Main Switch; (5)=Transformer;

(6)=Relays for heating elements; (7)=Neutral wire input; (8)=Level sensor for

built-in Scent Pump; (9)=Steam Room Exhaust Fan; (10)=Interface for built-in

Scent Pump; (11)=Drain; (12)=Solenoid Valve; (13)=Steam Room Temperature

sensor; (14)=Tank Temperature sensor; (15)=Water Level Probes; (16)= Dispenser

Unit Control

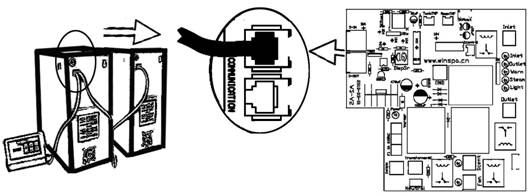

Connection of WinSpa Control to the PCB (Figure 11):

Installing Control Unit

Mount

the steam control unit on an accessible area outside the steam room. It is

recommended not to place the steam control near to showers or similar wet

places. Do not install the control unit inside the steam room! Never attempt to

modify or to fix the steam control. Ask your licensed technician or your

nearest dealer service center for repair. The control cable is recommended not

longer than 30 meters. Figure 12

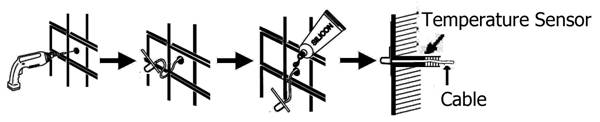

Installing the Temperature Sensor

Before

installation the generator must be switched off from main power supply.

The

temperature sensor comes along with the WinSpa steam generator. It is

recommended to use only WinSpa temperature sensor with WinSpa generator as it

may otherwise not function correctly. Temperature sensor wiring should not be

routed near power cables or hot areas as it may cause electronic interference

or damage to the wires.

1. The temperature sensor

has to be installed:

a. On a surface where there is no

obstruction below it.

b. Height has to be 1.5-1.7 meters

above the floor.

c. It should be away

from the steam head so that the steam will not hit the sensor directly.

The sensor has an

integrated 9-meter cable. If longer cable is needed, please consult your WinSpa

technician.

2. A 4mm hole is required to insert the temperature sensor. Do not create bigger or smaller hole. Clean the hole before inserting the sensor.

3. Either make a hole in

the cable lead-in on back of control unit to pull the cable through, or plug

the cable into the plinth on PCB inside generator. See figure 10.

4. Pull the temperature

sensor through the steam room wall. Do not apply staples or other material that

may damage the cable.

5. Insert the temperature

sensor into the steam room. Screw or glue the sensor to the wall

6. Apply silicone sealant

on the hole in the wall to create a moisture seal. Make sure there is no trace

of silicone on the sensor as it may interfere its reading. Figure 13

Steam Generator Series Connection (Figure 14)

Control Master Slave

1 Slave 2 …….

NOTE! In the event of faulty operation occurs in any one of

the slave units, a warning beep will alarm the user from the faulty generator,

however the rest of the generators can operate normally.

Troubleshooting

If an error occurs, the steam generator should be

switched off. There will be a warning beep sound to alarm the user every 2

seconds. There will be 3 different beep sounds.

See below Sound Indentification:

.

|

WINSPA Steam Generator Fault Code

Table

|

|

Code

|

Sound

|

Fault description

|

Maintenance

recommendations

|

|

E1

|

One Long Ring

|

Water tank temperature is too high,

the heating element may be in the dry burning

|

Power off immediatly & check

|

|

E2

|

Two Long Ring

|

Water inlet problem

|

Check water, pipe and the water

inlet electromagnetic valve

|

|

E3

|

Three Short Ring

|

Water outlet problem

|

Check the drainage pipe and a

drainage valve

|

|

E4

|

Four Short Ring

|

Short circuit on higher leg of water

level probe

|

Check the circuit board, see if any

touch between the probe heating element or tank,cleaning tank scale

|

|

E5

|

Five Short Ring

|

The scale is too much on higher leg

of water level probe

|

Clean the scale on the water level

probe

|

|

E6

|

Four Short Ring

|

Short circuit on lower leg of water

level probe

|

Check the circuit board, see if any

touch between the probe heating element or tank,cleaning tank scale

|

|

E7

|

Five Short Ring

|

The scale is too much on lower leg

of water level probe

|

Clean the scale on the water level

probe

|

|

{No}

|

{One Short Ring}

|

{No fault, the power-on completion}

|

|

IMPORTANT! only a qualified electrician or

maintenance personnel are allowed to make the service operations and repairs!

Checking and Fault-finding

In the event of faulty operation, first check the

following:

l

Are the control panel

and steam generator connected properly?

l

Is the steam generator

correctly installed in accordance with these instructions?

l

Dose the drainage pipe

slope down properly towards the waste outlet?

l

Is the filter clogged?

To clean the filter, disconnected the feed pipe, remove the filter and rinse it

free from particles of calcium carbonate and other deposits.

l

Are there any sharp

bends in the steam pipe? (the minimum permitted radius of bends is 50mm,2”)

l

Does the construction

and ventilation of the steam room comply with instructions?

Followings are for a quick check:

After generator is powered on, the display on control

panel shows  .

.

Cause:

The temperature sensor on water tank is loose connected.

Solution: Disconnect the power supply to steam generator, open

the front cover of the generator. Tighten the spade connector on the tank using

a cross screwdriver.

The display on control panel shows  and

time alternatively:

and

time alternatively:

Cause:

The steamroom temperature sensor is loose connected to the control panel – or

to the main circuit card (steamroom temperature sensor can be either connected

to control panel or to the main circuit card inside the steam generator).

Solution: Disconnect it and plug it in again properly.

Cause:

the steamroom temperature sensor is faulty.

Solution: Replace a temperature sensor.

Chicklist

Steam generator buzzes all the time

|

Causes

|

Solution

|

|

Tap water

pressure is too low and/or the filter is clogged which cause unstable

incoming water flow

|

Increase

the water pressure or clean the filter

|

|

Solenoid

valve for water supply has stuck or been defective.

|

Clean

or replace the solenoid valve

|

|

Malfunction

CPU of main circuit board is defective

|

Important! Always keep the fan inside generator working to cool

the air around CPU and replace the faulty component

|

|

The

water level probes are coved by excessive calcium carbonate deposits, or the

internal diameter of the steam pipe is considerably reduced which may cause a

too great high temperature in water tank, or heating elements are drying

burn.

|

Clean

or replace the level probes

Replace

the pipe or the pipe joint which is causing the reduction; refer to Steam

Outlet on page 12

|

|

Drainage

valve has stuck by calcium carbonate deposits or been defective

|

Clean

or replace the drain valve

|

The steam room

maintains the desired temperature (40-500C, 105-1220F), but no steam is produced

|

Causes

|

Solution

|

|

Cause: Insufficient ventilation in the steam room

|

Increase

ventilation. The ventilation is insufficient if less than 10-20 cubic

meters(13-28 cub.yd) of air per person per hour is evacuated via the outlet

vent.

|

|

Cause: The air coming into the steam room is too warm

|

Reduce

the intake air temperature to 350C (950F)

|

|

Cause: The ambient temperature is higher that 350C (950F)

|

Ensure

that the ambient temperature does not exceed 350C (950F)

|

|

Cause: The thermometer is faulty or wrongly placed.

|

The

thermometer should be placed approximately 170cm (67”) above floor level and as far away from the steam jet as possible.

|

Erratic steam production right from the start.

|

Causes

|

Solution

|

|

Cause: The steamroom thermostat sensor

is

wrongly placed in relation to the steam jet.

See

TEST 1.

|

Move

the sensor or alter the direction of the steam jet.

|

|

Cause: Calcium carbonate or other foreign

bodies

in the filter.

|

Remove

and clean the filer.

|

The steam room requires an abnormally long time to

heat up

|

Causes

|

Solution

|

|

Cause: The generator is not powerful enough. See Table on Page

13

|

Replace

the steam generator with one with a higher heat output.

|

|

Cause: Excessive ventilation in the steam room.

|

Reduce

the ventilation to evacuate 10-20 cubic meters (13-26 cub.yd) of air per

person per hour.

|

|

Cause: The ambient temperature is lower than 150C (590F)

|

Increase

the ambient temperature or replace the steam generator with a more powerful

one

|

|

Cause: Heating element is broken.

|

Replace

heating elements.

|

|

Cause: The steam room thermostat sensor is too close to the

steam jet. See TEST 1.

|

Move

the sensor or change the direction of the steam jet.

|

Neither steam nor heat is generated in the steam room

|

Causes

|

Solution

|

|

Cause: Control box is incorrectly set

|

Check

the time and temperature on the control box

|

|

Cause: The water is not reaching the steam generator.

|

Open

the tap connected to the piping to allow incoming water to flow into the

steam generator.

|

|

Cause: The filter is clogged

|

Remove

the filter and clean off any metal filings or other foreign bodies.

|

|

Cause: The solenoid valve for water supply has stuck or been

defective.

|

Remove

the solenoid valve and clean off any metal filings or other foreign bodies.

Or replace a solenoid valve.

|

|

Cause: Excessive calcium carbonate deposits in the steam

generator's water tank.

|

Clean

the water tank by following steps of Tank Cleaning on page 10

|

|

Cause: Malfunction in the circuit board or control panel.

|

Replace

the faulty component.

|

|

Cause: The steam generator is wired up for the wrong voltage

|

Check

the voltage and the connection to the generator. See Figure 10 on page 14.

|

|

Cause: The heating element is broken

|

Replace

the defective heating elements.

|

A continuous trickle of hot water from the steam

generator’s drainage pipe.

|

Causes

|

Solution

|

|

Cause: The drainage valve has stuck or been defective.

|

Disconnect

the power supply to steam generator, remove the drainage valve and clean it.

If the fault persists after cleaning, replace a drainage valve.

|

Hot water comes out of the steam head in spurts or in

a slight, even flow mixed with steam.

|

Causes

|

Solution

|

|

Cause: Small water pocket along the steam pipe.

|

Eliminate

the water pocket by sloping down the steam pipe to steam room.

|

|

Cause: The steam pipe is uninsulated along too great a portion

of its length.

|

Insulate

the steam pipe.

|

Pressure Relief Valve opens / is activated.

|

Causes

|

Solution

|

|

Cause: The steam pipe is blocked.

|

Remove

the blockage.

|

|

Cause: The internal diameter of the steam pipe is considerably

reduced.

|

Replace

the pipe or the pipe joint which is causing the reduction; refer to Steam

Outlet on page 12

|

|

Cause: Sharp bends along the steam pipe. See TEST 2.

|

Take

out the sharp bends in the pipe. Bends are to be gently rounded (minimum

radius 50mm, 2").

|

|

Cause: Large water pocket somewhere along the steam pipe. See

TEST 2

|

Adjust

the steam pipe to eliminate the water pocket.

|

|

Cause: Excessive calcium carbonate deposits in the steam

generator's reservoir.

|

Clean

the water tank. See Tank Cleaning on page 10

|

TEST 1

Temperature sensor test.

Soak a small towel in cold water. Hang the wet towel

over the thermostat sensor. If, within 20 minutes, the steam generator has

started to produce steam continuously, the equipment is not defective, but the

thermostat sensor is located in an unsuitable position, or the thermostat

itself is faulty. If steam production does not begin, use the checklist to find

out the cause.

TEST 2

Steam pipe test if the pressure relief valve is

activated.

Disconnect the steam pipe from steam generator. Start the

generator and let it remain on for about 10 minutes. If the pressure relief

valve is not activated during this test, there is a blockage along the steam

pipe which is preventing the passage of steam. Take the necessary steps

according to the information in the checklist.

TEST 3

Steam generator beeps all the time but no faulty parts

can be found.

Switch off the steam generator by pressing on/off on

control panel after operating 20 minutes or when beeps, the display shows

current temperature of the water tank. use the checklist to find out the cause.

Limited Warranty - WS Steam Generator

Two-Year

Warranty

WinSpa warrants

the control system, water tank and transformer for a period of two year from

the original purchase date. Warranty on the factory installed spare parts

specially covers the heating elements, inlet valve, drainage valve and exhaust

fan for a period of 6 months from the original purchase date. Refurbished

parts may be used to satisfy warranty replacement of electrical and mechanical

parts.

WinSpa reserves

the right to inspect or designate a person to inspect any part that is claimed

to be defective and covered by this warranty.

Any and all

additional cost and fees including shipping, delivery, freight, set-up,

installation, upgrade fees and disposal charges will be the responsibility of

the steam generator owner.

Acts

Invalidating Warranty

Warranty

conditional upon proper installation under this instruction manual and regular

basic maintenance, including regular removal of calcium and cleaning the water

tank and electrodes.

This warranty is

void if the steam generator has been subjected to alterations, neglect, misuse

or abuse; if any repairs have been attempted by anyone other than an authorized

serviced representative; or if failure caused by accident, acts of nature or

other causes beyond the control of Winspa.

Disclaimers

WinSpa shall not

be held liable for injury or loss of use of your steam generator or other

incidental and consequential cost, expense or damage, whether incidental or

consequential, arising out of any defect covered by this Limited Warranty,

including, without limitation, loss of use of the steam generator and cost of

removal of defective product, even if WinSpa has been advised of the

possibility of such damage. In no event shall WinSpa be liable for any reason

or cause in excess of the amount paid for the product by the dealer.

Coverage under this Limited Warranty shall commence as

of the original date of purchase or as otherwise outlined above and the

duration of such coverage shall not extend for any reason whatsoever beyond the

stated time periods. No other warranties, written or implied, are valid.

To apply for warranty following details must be

forwarded to WinSpa by email within 30 days of installation:

1.

Model number of steam

generator

2.

Serial number of steam

generator

3.

Date installed.

4.

Name of installer

5.

Name of customer

6.

Water filter installed

( Yes / No )

Table of Spare Parts Replacement

|

Spare Parts#

|

Model

|

Series No.

|

Replacement Date

|

|

Main

Circuit Card (PCB)

|

WS_____

|

|

_____/_____/_____

|

|

Control

Panel

|

WS_____

|

|

_____/_____/_____

|

|

Water

Level Probe

|

WS_____

|

|

_____/_____/_____

|

|

Steamroom

Temperature Sensor

|

WS_____

|

|

_____/_____/_____

|

|

Heating

Element

|

WS_____

|

|

_____/_____/_____

|

|

Transformer

|

WS_____

|

|

_____/_____/_____

|

|

Water

Inlet Valve

|

WS_____

|

|

_____/_____/_____

|

|

Drainage

Valve

|

WS_____

|

|

_____/_____/_____

|

|

Pressure

Relief Valve

|

WS_____

|

|

_____/_____/_____

|

|

Exhaust

Fan

|

WS_____

|

|

_____/_____/_____

|

|

Fragrance

Feeding Pump

|

WS_____

|

|

_____/_____/_____

|

|

Steamroom

Exhaust Fan

|

WS_____

|

|

_____/_____/_____

|

|

Others______________________

|

WS_____

|

|

_____/_____/_____

|

www.winspa.cn

Subject to change without

prior notice